FotoDevelopment

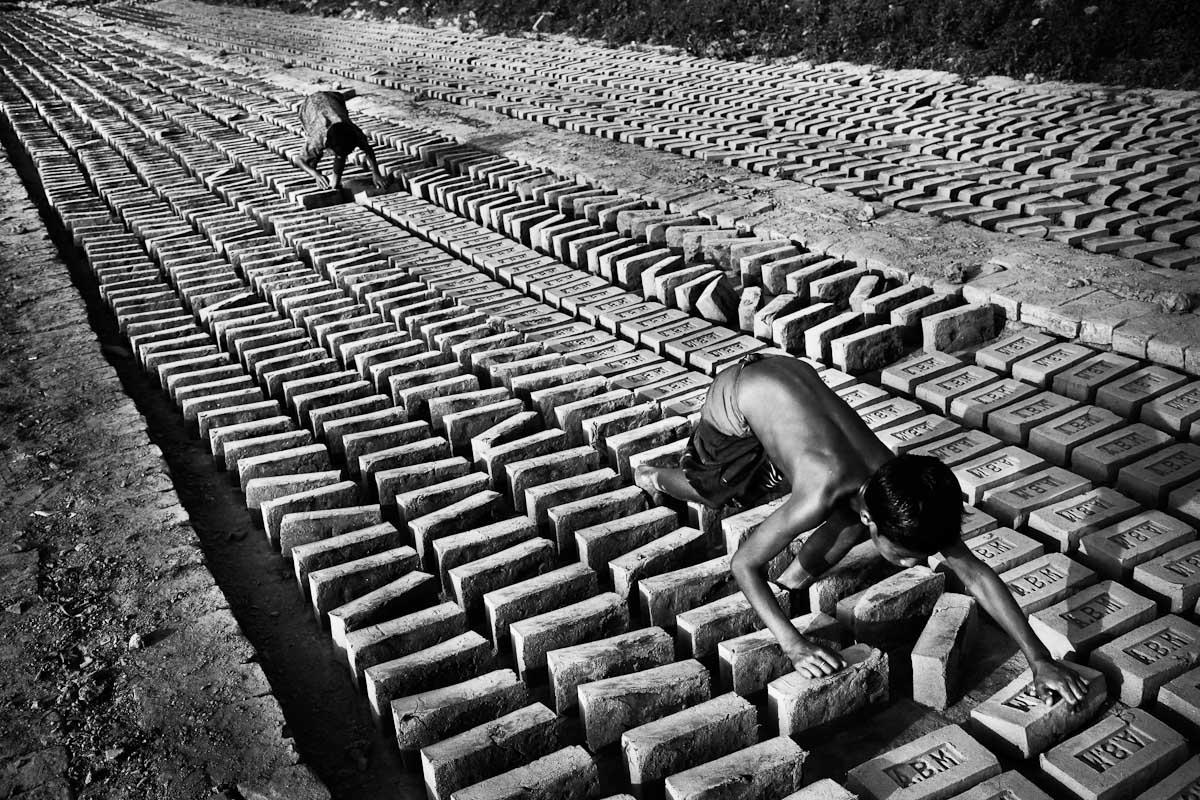

Green Bricks of Bangladesh by Khaled Hasan

Khaled Hasan has documented old and new brick kiln technology in his home country of Bangladesh. He compares 150-year-old traditional brick kiln technology which is energy and resource intensive and has negative environmental impacts such as land degradation, depletion of water resources and deforestation with new imported Hybrid Hoffman Kiln (HHK) technology which is less resource intensive, more energy efficient, more productive and which produces significantly less carbon emissions.

Every year a staggering 8.6 billion bricks are produced in Bangladesh from over 8,000 brick kiln sites, a number which increases annually at a rate of 5.2% with the upward trend in urbanisation. Traditional brick making in Bangladesh produces a toxic mix of carbon monoxide, sulphur dioxide and ash, which are harmful to both human health and the environment. Most of the brickfields in Bangladesh employ low wage labourers on a seasonal basis who reside in basic accommodation with poor sanitation. The work is both physically demanding and dangerous but the workers receive little protection or healthcare.

A new UNDP project, supported by the Global Environment Facility, uses Hybrid Hoffman Kiln (HHK) technology imported from Germany to make green bricks. A single new kiln can produce 15 million bricks annually (instead of 100,000) and carbon emissions from each kiln are reduced by as much as 5,000 tons per year. The new kilns are less resource intensive and far more efficient as they use internal fuel and reuse waste heat. The HHK technology also creates better working conditions; the mechanised processes reduce the need for hard manual labour which particularly benefits the women, the workers have adequate protective gear and the provision of year round work creates economic stability in the workforce.

Whilst they contribute significantly to the economy, they cause irreversible harm to human health and the environment.

Further, 33% of the kilns use firewood, which is a significant cause of deforestation in Bangladesh.